Schoolhouse Rock was an animated Saturday morning children’s television series that aired on ABC from 1973 to 1979. Despite it having been taken off the air many years ago, schools today can use it to educate students about various grammar, math, history, and government topics. We bring this up because of one episode in particular: I’m Just a Bill. In this episode, a rolled-up piece of paper tells his story about starting as an idea and going through the proper channels of government to become a law. Being in the recycling business, this got us thinking about the rolled-up piece of paper itself, and if students ever wonder, how was the paper created for the bill to be written on? Did the bill contain any recycled paper? Furthermore, what does the lifecycle of recycled paper look like?

These are difficult questions, and since we are glass-half-full kind of people, we imagine there are plenty of students out there today who really want to know the answer. That’s what this blog article is intended to accomplish.

Texas Recycling: A Dallas Recycling Facility for Metal, Cardboard, Recycled Paper and More! Call 214-357-0262

The Lifecycle of Paper: The Beginning

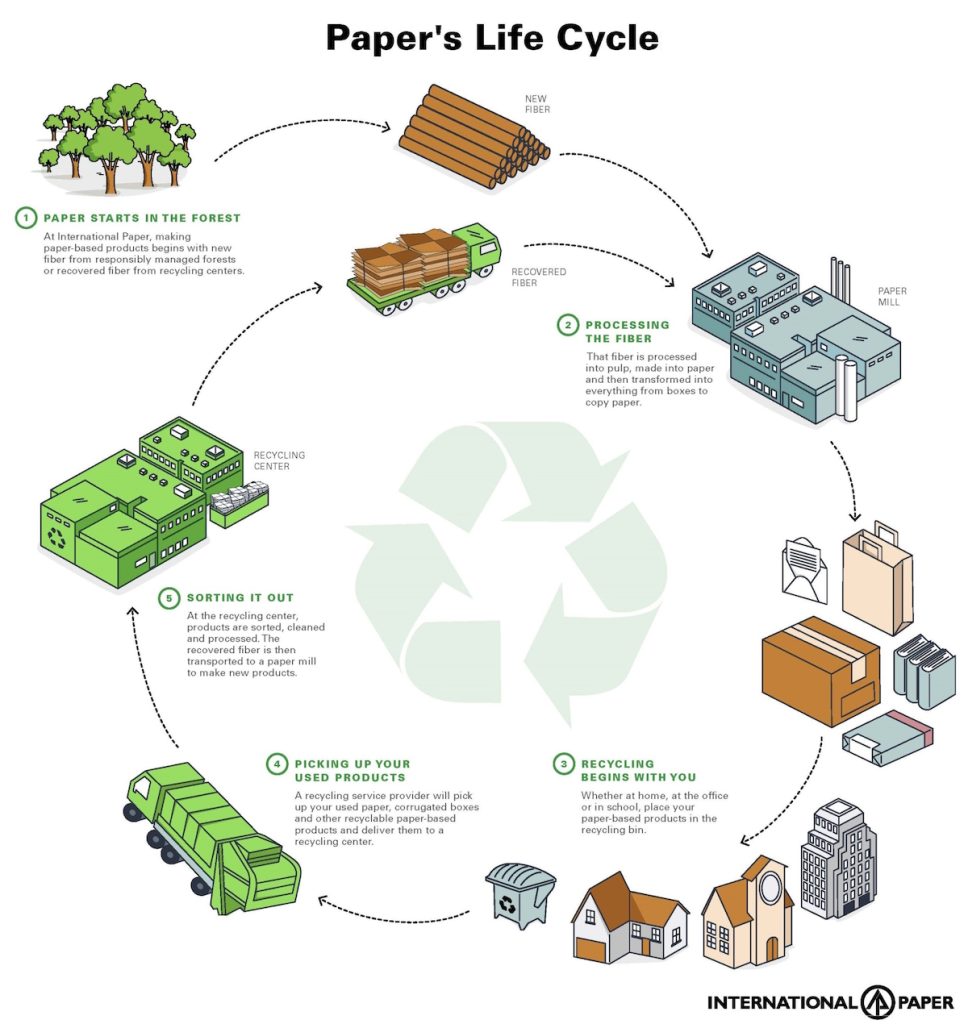

For now, let’s assume paper is made with all new raw materials and not combined with any recycled paper content. Paper manufacturing begins with cellulose fibers, which are harvested from wood. Most paper manufacturers that use virgin materials source their wood from sustainable forests. Also, environmentally responsible manufacturers strive to utilize local forests, thus minimizing transportation costs and emissions. Or paper factories may partner with sawmills and furniture manufacturers and repurpose leftover wood.

From there, the next step in creating paper is to make the pulp. The wood is combined with water and either cooked at high pressure to free the cellulose fibers or placed in a grinder to separate the fibers. The method affects the fiber length and, therefore, the type of paper the pulp will produce. For instance, cooking or chemical pulping results in stronger, longer fibers. Conversely, grinding, or mechanical pulping, produces shorter fibers.

Once the fibers are separated, the pulp is washed. If you’re making white paper, the pulp is also bleached. At this point, the pulp mixture is quite diluted, so it is placed onto mats to drain. Vibration is used to help the fibers within the pulp interlock and create sheets. Next, the sheets are passed through rollers to press the paper and squeeze out any additional moisture. The paper is also steam-heated to dry.

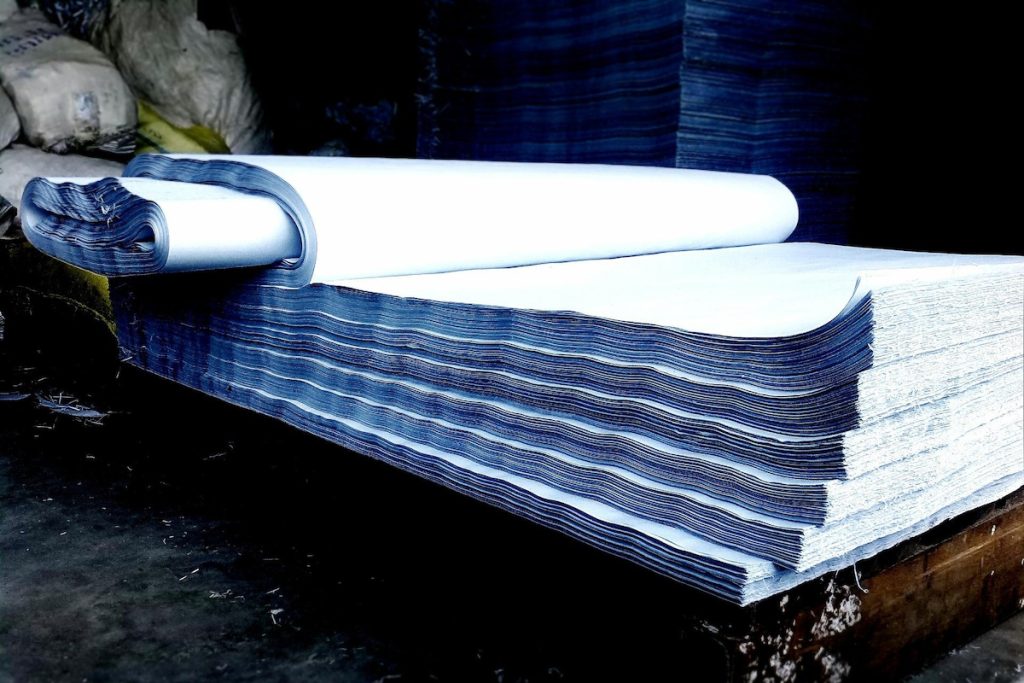

Once dry, the paper is calendared, or polished and smoothed, then made into rolls that can be transported to the makers of paper products.

Photo credit: International Paper

Next Steps: Utilized and Recycled

Once the paper is made into notebook paper, cards, wrapping paper, invitations, printer paper, and various other products, it ends up in the hands of businesses and consumers. The paper is used for its intended purpose, and then it may no longer have value to the end user.

Hopefully, after the final use, the paper is placed in a recycling bin so it can continue its destiny as recycled paper.

If the paper is thrown in the trash at this point, the lifecycle of paper will sadly end. The paper does not achieve the next level of becoming recycled paper. Unfortunately, it ends up in a landfill to decompose or is incinerated into ash.

Texas Recycling: Our Dallas Recycling Center Helps Your Business with Revenue by Accepting Items to Become Recycled Paper. Call 214-357-0262

The Lifecycle of Paper Continues: Recycled Paper

Paper can be recycled several times—about 4-7—before the cellulose fibers are too broken down to produce quality paper. The benefits of using recycled paper for pulp include:

- Less energy is used

- Less water is used

- Fewer emissions due to less transportation of raw materials and less incineration of waste

- Fewer trees are being cut down

- Less waste in landfills

Used paper is then collected through community or commercial recycling programs. It is sorted and distributed to be reprocessed into pulp at paper manufacturers. At the pulp mill, the recycled paper is combined with water and blended to separate the fibers. The pulp then undergoes various processes to be cleaned. These steps remove ink, dirt, and other contaminants. The pulp then undergoes a similar process to that of virgin pulp to produce long rolls of paper.

Some pulp mills produce pulp from all recycled paper. Others mix virgin materials with recycled materials to produce their pulp. The next time you buy paper, take a closer look at the label. Likely, you will be able to learn the percentage of recycled products in your purchase.

The Lifecycle of Paper Must, Too, Come to an End

The lifecycle of paper continues until the fibers are no longer usable. At this point, the piece of paper has been recycled multiple times, knowing it has done its part in helping the environment and reducing waste. Just like the bill wanting to become a law, each piece of paper wants to stay around longer, be pulped again, and return as recycled paper multiple times.

Prolong the Lifecycle of Paper With Texas Recycling

Does your company want to prolong the lifecycle of paper with a customized recycling program? Texas Recycling works with businesses to recycle responsibly and affordably.

Like you, we at Texas Recycling are concerned about the future of our environment. We offer customized recycling solutions tailored to your specific recycling needs, helping you achieve your business goals. Our professional and personalized service will exceed your expectations.

While we are a leader in recycling aluminum, paper, cardboard, stainless steel, and steel, we also handle various metals for our commercial and industrial volume clients. Texas Recycling is dedicated to improving the environment by providing the highest-quality recycling services in the DFW Metroplex. Our creative solutions help companies embrace environmental responsibility and sustainability.

From scheduled pickups for large commercial entities to our Public Buy Back Center for individuals and smaller businesses, we have a recycling solution to meet your needs.

Help the environment and your bottom line by calling Texas Recycling at 214-357-0262 to get started on a commercial recycling or industrial recycling program for your organization.